Packing the Right Way: Why It Matters More Than You Think (And How Weigh N Pack Gets It Right)

In the world of manufacturing and distribution, packing is often viewed as a simple, final step before a product reaches its destination. But the truth is, packing is much more than just wrapping or boxing up an item. It is a critical phase that ensures product safety, preserves quality, and even reflects brand reliability. When done right, packaging can enhance customer satisfaction, improve operational efficiency, and reduce costs. Yet, many businesses still underestimate its importance — and that’s a costly mistake.

Let’s explore why packing the right way matters more than you think and how leading practices in the industry have elevated this process to an art and a science.

Why Proper Packing is Crucial in Every Industry

No matter the sector — whether it’s food, pharmaceuticals, electronics, or consumer goods — proper packing plays a pivotal role in protecting the product's integrity throughout the supply chain. Improper packaging can lead to spoilage, damage, contamination, or even legal liabilities. The packaging needs to withstand handling, transport stress, varying climatic conditions, and shelf time, all while maintaining the product’s original condition.

Moreover, packaging isn’t just about protection. It directly influences a customer’s first impression. A well-packed product not only looks appealing but also reassures customers about the brand's commitment to quality and detail. On the flip side, damaged or shoddy packaging can tarnish a brand's image and lead to poor reviews, returns, and loss of repeat business.

The Hidden Costs of Poor Packaging

When packaging is not done right, the consequences can be financially draining:

Product Returns and Refunds: Damaged goods lead to returns, replacements, and refunds, all of which hurt the bottom line.

Increased Shipping Costs: Inefficient packing leads to higher weight and volume, which translates to inflated shipping expenses.

Wastage of Resources: Using excessive or inappropriate materials not only costs more but is also environmentally unfriendly.

Operational Delays: Packaging errors can disrupt the supply chain, causing delays that affect customer satisfaction and business operations.

It’s evident that effective packaging is both a cost-saver and a quality enhancer. Businesses that master the art of packing can gain a competitive advantage in crowded markets.

Elements of Effective Packaging

There are several elements that define effective packaging:

1. Material Selection

Choosing the right material is foundational. Whether it’s plastic, glass, metal, or eco-friendly alternatives, the material must suit the product’s requirements, ensuring protection against moisture, light, impact, or contamination.

2. Appropriate Sizing

Overpacking not only increases costs but also contributes to environmental waste. On the other hand, underpacking exposes products to damage. Finding the right balance with precise sizing is key.

3. Labeling and Information

Clear labeling provides necessary information about handling, storage, expiry, and usage instructions. This is particularly critical in sectors like pharmaceuticals and food where compliance with regulations is mandatory.

4. Automation and Technology

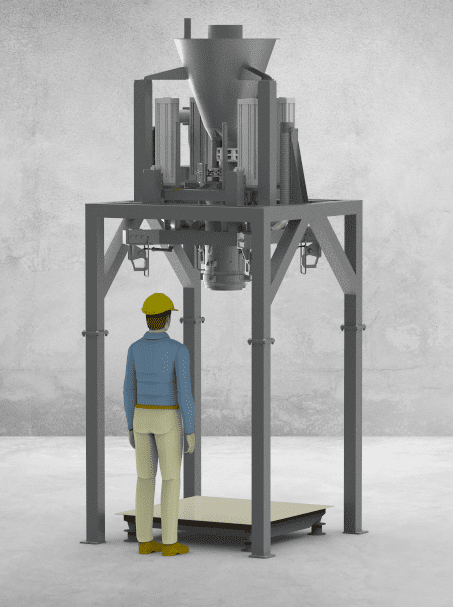

Modern packaging solutions often involve automated machinery, ensuring consistency, speed, and accuracy. Technology like weighing systems, conveyors, and sealing equipment helps maintain standardization, reducing human error.

How Industry Leaders Get Packaging Right

Forward-thinking companies are investing in smart packaging technologies to stay ahead. Precision weighing, intelligent conveyor systems, and automated filling and sealing processes are being widely adopted to enhance efficiency and reliability.

This is where Weighnpack stands out. Their solutions are designed to address these very challenges by offering cutting-edge packaging systems that combine accuracy with speed. By integrating smart automation, they help businesses reduce waste, minimize human error, and optimize packing processes for maximum efficiency.

Sustainability in Packaging: A Growing Necessity

As sustainability takes center stage globally, the packaging industry is rapidly evolving. Eco-conscious consumers and regulatory bodies are demanding greener packaging solutions. Companies are now expected to reduce their carbon footprint by adopting biodegradable materials, reducing plastic usage, and creating recyclable or reusable packaging.

Innovative companies, including Weighnpack, recognize the importance of sustainability. By incorporating environmentally friendly practices within their solutions, they contribute not just to operational efficiency but also to the planet’s well-being.

How to Optimize Your Packaging Process

If you’re a business looking to optimize your packaging process, here are some best practices:

Evaluate Your Packaging Materials Regularly: Materials that were effective a few years ago might not be the best choice today. Stay updated with innovations in sustainable packaging.

Invest in Technology: Automation reduces costs in the long term by enhancing speed, reducing errors, and ensuring consistency.

Train Your Workforce: Even with automation, a knowledgeable workforce is essential to oversee operations and maintain quality control.

Prioritize Customization: Tailor your packaging solutions to your product needs instead of using a one-size-fits-all approach.

Monitor Performance Metrics: Keep track of packaging-related KPIs such as material usage, waste, damages during transit, and return rates to identify areas of improvement.

Final Thoughts

Packaging is no longer just an operational necessity — it is a strategic component of business success. From protecting products and reducing costs to boosting brand image and supporting sustainability, getting packaging right has far-reaching benefits.

As businesses navigate competitive markets, it’s essential to view packaging not as a cost center but as an investment in quality, efficiency, and customer satisfaction. Brands that prioritize smart, sustainable, and efficient packaging solutions will inevitably stand out.

Whether you’re looking to improve product safety, reduce operational costs, or meet sustainability goals, choosing the right packaging partner and approach is key. In a world where every detail matters, packing the right way is not just an option — it’s a business imperative.

- Art

- Causes

- Best Offers

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Festival

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness