5 advantages of outdoor Co-extrusion WPC decking

In today's society, with the enhancement of people's awareness of environmental protection, green building materials have gradually become the first choice for architecture and interior decoration.

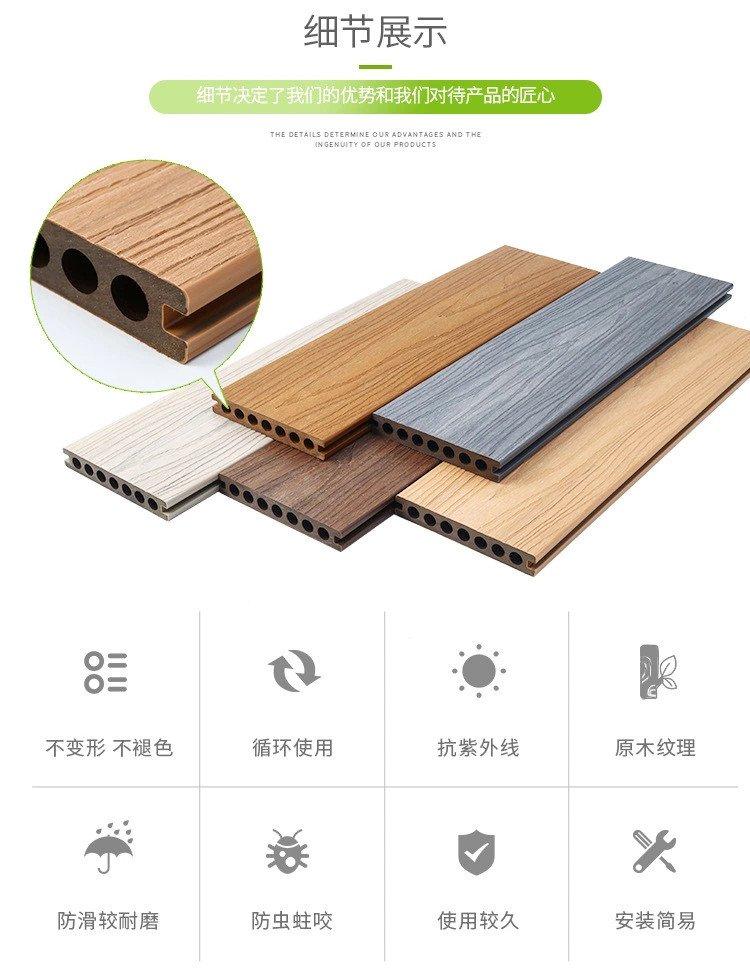

WPC co-extrusion flooring, as a new kind of green and environmental protection floor material, has been widely concerned and used because of its unique performance and environmental protection characteristics.

The basic material composition of wood-plastic co-extruded flooring is an important source of its environmental properties.

The core layer of such flooring is usually made from a mixture of recycled wood flour, plastic and other additives, while the top layer is processed with a high-performance protective film through co-extrusion technology.

This structure not only makes the wood-plastic co-extruded floor closer to natural wood in appearance, but also greatly improves its waterproof, moisture-proof, UV resistance and wear resistance.

More importantly, it does not use formaldehyde and other harmful substances in the production process, and is a truly safe and environmentally friendly material.

From the performance point of view, wood-plastic co-extruded floor has many advantages.

For example, its excellent waterproof and moisture-proof performance makes it suitable for humid environments such as kitchens and bathrooms; Strong durability, anti-UV, anti-corrosion, anti-mildew, can maintain a longer service life; Smooth surface is easy to clean and maintain, stains are easy to clean, simple maintenance; Easy to install, the use of plug-in design, convenient and quick to complete the installation, without complex construction process.

In terms of use and maintenance, although the maintenance of WPC flooring is relatively simple, proper cleaning and maintenance is still very important.

Usually you can use a soft broom or electrostatic mop for daily cleaning, for more stubborn stains, you can use neutral detergent and wet cloth to wipe.

Avoid using abrasive tools to clean the floor to avoid scratching the surface.

The application scenarios of wood-plastic co-extruded flooring are very wide. [1]

It is not only suitable for home interiors such as living rooms, bedrooms, kitchens and bathrooms, but also for commercial Spaces and public places such as offices, hotels, schools and medical institutions.

Its superior performance can adapt to the needs of a variety of different environments.

WPC co-extruded decking occupies a place in the flooring material market due to its environmental protection, durability and aesthetics.

The choice of wood-plastic co-extruded floor is not only the pursuit of home aesthetics, but also a responsible performance of environmental protection.

With the enhancement of consumer awareness of environmental protection and the continuous progress of technology, the future market prospects of wood-plastic co-extruded flooring are promising, and it is expected to be applied in more families and public Spaces.

Garden wood plastic co-extruded decking because of its unique performance and environmental protection, has become the new darling of outdoor decoration materials.

This flooring made of wood-plastic composite material (WPC), processed by advanced co-extrusion technology, not only looks close to natural wood, but also has excellent waterproof, moisture-proof, UV resistance and wear resistance in terms of functionality, fully meeting the needs of modern home and public places.

The core layer of wood-plastic co-extruded floor is mainly made of wood flour, plastic and some additives, and the surface layer is added with a layer of high-density protective film through co-extruded technology. [1] [2] [3]

This structural design not only enhances the structural strength of the board, but also provides additional protection, making the floor more durable and extending the service life.

It is worth mentioning that formaldehyde and other harmful substances are not used in the entire production process, which guarantees the safety and environmental protection standards of the products.

In terms of performance, the wood-plastic co-extruded floor has significant environmental safety characteristics, does not contain harmful substances, can be recycled, and has little impact on the environment. [1] [2]

Its excellent waterproof and moisture-proof performance makes it suitable for kitchen, bathroom and other humid environment; Strong durability, UV resistance and corrosion resistance ensure that the floor will last as long as new, even in harsh conditions.

In addition, the surface of the floor is smooth, easy to clean and maintain, and installation is extremely simple, which can be done quickly with the plug-in design.

- Art

- Causes

- Best Offers

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Festival

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness